ThermAvant Technologies Attains Class 1 Certifications for Three Vacuum Aluminum Braze Ovens Operating From Columbia, MO Facility

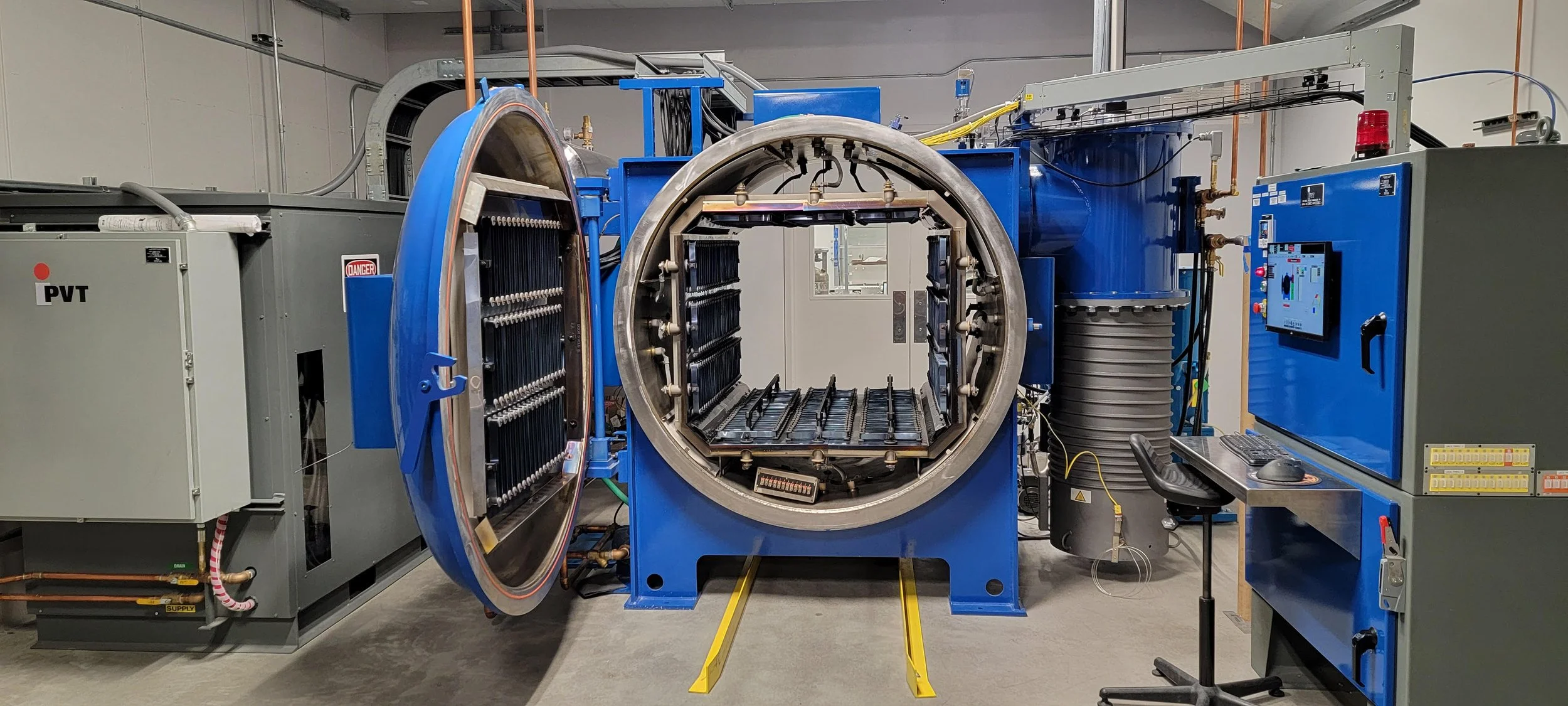

[Columbia, Missouri] - ThermAvant Technologies proudly announces the achievement of Class 1 Certifications for its three active Vacuum Aluminum Braze (VAB) ovens. The certifications were overseen by Aerospace Testing and Pyrometry (ATP), third-party pyrometry experts. The ovens operate from ThermAvant Tech’s 43,000 square-foot, AS9100/ISO9001 certified campus in Columbia, MO.

VAB is one of ThermAvant Tech’s critical processes for bonding aluminum oscillating heat pipes and microchannel cold plates. VAB is a relatively clean, fluxless method and avoids the stress and distortion of welding. ThermAvant Tech uses VAB in conjunction with its micromachining and etching capabilities to produce aluminum structures with internal, hermetically sealed 2- and 3-D microchannel patterns in complex configurations—and does so at variable prices far below those of state-of-the-art additive manufacturing methods.

“I am extremely proud of the engineers, metallurgists, and manufacturing team here who have over a hundred years of combined experience for earning this certification. This milestone highlights ThermAvant Tech’s commitment to being not only the world’s most innovative developer of Oscillating Heat Pipes (OHPs) and microchannel coldplates but also the most reliable manufacturer of mission-critical, vacuum aluminum brazed hardware for Department of Defense and commercial aerospace and high-technology applications,” says Joe Boswell, CEO of ThermAvant Technologies.

Today, ThermAvant Tech has three active aluminum vacuum braze ovens: two made by PVT Inc. and one by Furnacare Inc. All three are now Class 1 certified, ensuring precise temperature control, meeting or exceeding strict aerospace pyrometry requirements. ThermAvant Tech is presently commissioning its fourth VAB oven made by Ipsen, Inc. for certification and operation in late 2024 as demand for its OHP-based products continues to accelerate.

ThermAvant Techs 's Class 1 certifications meet the rigorous specifications outlined by industry standard AMS-2750G. With these ovens ThermAvant Tech can produce joints to AWS C3.7 Class A, B or C requirements. In addition, ThermAvant Tech validates the reliability and precision of VAB hardware with additional quality assurance tests, including.

Helium leak check

Proof and burst pressure

Flow rate and pressure drop

Internal volume vs design volume

X-radiography

Metallurgical examination and microscopy

Thermal resistance

Shock, vibe, thermal cycling and accelerated aging

———

About ThermAvant Technologies:

ThermAvant Technologies is a designer and manufacturer of advanced thermal-mechanical solutions, and the world leader in the Oscillating Heat Pipe (OHP) technology. With more than $40 million of R&D funding, ThermAvant Tech helps partners compete by optimizing performance of their advanced military and commercial platforms where maximizing power and reliability while minimizing size and weight is mission-critical. ThermAvant Tech’s intellectual property portfolio includes patents and proprietary trade secrets. ThermAvant Technologies is headquartered at its AS9100D-certified engineering, testing and manufacturing campus in Columbia, MO where its team creates the world’s most efficient thermal technologies to make the world a safer, more productive place for current and future generations.