Albedo’s Application

Very Low Earth Orbit Mid-size Satellite Thermal Control System (VLEO TCS)

VLEO TCS Requirements

Maximize thermal conductance from payloads to remote radiators

Minimize thickness and weight of meter-scale 3D heat pipes

Reduce lead time from concept of design to flight hardware to <12 mo.

Simplify assembly with upstream payloads and downstream structures

Lower total cost for recurring hardware and non-recurring engineering

ThermAvant Tech’s Deliverables

Design Reviews Concept of Design through End Item Data Packages

OHP Radiator isothermal heat rejection from bus to deep space

OHP Transporter 3D heat transfer within bus from payloads to radiators

OHP Payload Spreader in-plane heat spreading from critical devices

Trade Study Results

Albedo considered OHP-based solutions and Constant Conductance Heat Pipes (CCHPs), after quickly ruling out advanced solid materials such as annealed pyrolytic graphite due to inadequate thermal conductivity. Aluminum axially grooved CCHPs (13mm OD) can transport heat loads across meter-scale distances at low thermal resistances (e.g., <10 °C per 100 W-m), and Aluminum honeycomb radiators embedded with CCHPs (27mm combined thickness) can spread-and-reject such loads at equally low resistances.

Fig. 1 illustrates OHP transporters and radiators performing similarly to CCHPs but at thicknesses of 1-4mm, allowing tighter bend radii and higher specific power densities (i.e., 70% lower total volume). At the payload-level, OHPs integrate directly into baseplates (spreaders) for ease of assembly and reduced thermal resistance from key devices to radiator by as much as 50%.

Albedo decided an OHP-based TCS offered superior performance plus mass-volume savings; and, with ThermAvant Tech as its TCS partner, Albedo lowered cost-complexity to keep its VLEO satellite on budget and on schedule.

Figure 1. Comparison of OHP (left) and CCHP (right) VLEO TCS

Design Results

Next, Albedo and ThermAvant ran dozens of OHP design iterations, including limits models and simulations of alternative TCS layouts. Fig 2 is an OHP-based TCS temperature prediction as heat flows from payload-level OHPs (C, E and F) through 3D OHP heat transporters (B and D) to a single OHP radiator (A). The OHPs modeled are 3-4 mm thick. Total simulated heat is 215 Watts, and total temperature rise (dT) from hottest Payload OHP surface to coolest OHP Radiator surface is 10 °C (or less than 0.05 °C/W). The OHP-based TCS’ total mass is 3.0kg, approx. 30% less than a CCHP-based TCS’.

Figure 2. Thermal simulation of OHP-based VLEO TCS (Power 215W, Temperature °C)

Manufacturing Results

From its 43,000 ft2, AS9100D/ISO9001-certified facility in Columbia, MO ThermAvant built Phase 1 Engineering Models (EM) and then final Phase 2 Flight Models (FM) – see Fig. 3’s redacted photographs.

To manufacture OHPs, ThermAvant utilized internal high-speed, multi-axis CNC milling centers, Aluminum vacuum braze ovens, precision presses, laser welders as well as its proprietary back-of-the-line fluid processing and quality assurance resources to meet Albedo’s quality, cost and timing specifications.

Once produced, each OHP undergoes He leak testing to <10-8 cc/sec, proof volume and pressure testing, plus high- and low-temperature soaking before functional testing. EM units go through more rigorous non-destructive and destructive examination to ensure flight worthiness of the OHPs’ critical features and ThermAvant’s special processes to make them.

In addition, Albedo and ThermAvant designed and built custom thermal testing vehicles (TTVs) to verify operability and survivability of the OHPs under replicated storage, assembly, launch and on-orbit conditions – see Testing Results.

Figure 3. Photographs of OHP hardware for VLEO TCS

Testing Results

Engineering Model (EM) and Flight Model (FM) OHPs go through a battery of thermal and mechanical tests to verify performance. Fig. 4 presents an OHP Transporter on a TTV to validate preliminary design predictions under a 75-hour repeatability test in horizontal configuration to simulate on-orbit, low-gravity conditions. When cycled between 25% and 150% of nominal operating power, the OHP maintained ultra-low thermal resistance of 0.03 °C/W, equivalent to approx. 100,000 W/m-K thermal conductivity.

Likewise, OHP Payload Spreaders and OHP Radiators met their predicted thermal performance requirements. The FM OHPs satisfied Albedo’s stringent mass plus dimensional specifications as verified through First Article Inspections prior to shipment; ensuring easy assembly and installation at Albedo with their balance of spacecraft subsystems and structures.

Figure 4. TTV and thermal reliability test results of OHP Transporter (details obfuscated)

Conclusion

Albedo and ThermAvant successfully designed and completed the world’s first OHP-based thermal control system for very low earth orbit mid-size satellites, where OHPs conduct heat from multiple payloads through 3D transporters and reject across meter-scale radiators. And, they’ve done so under an accelerated time schedule. The OHP-based TCS offers these advantages over conventional CCHP-based TCS:

30% less mass and 70% less volume of total heat pipe TCS

33% lower temperature rise from payloads to radiators

100% increase in TCS’ specific thermal conductance (W/K-kg)

Qualitative benefits include: integral, tight-tolerance OHP interface plates for easy assembly with upstream payloads and downstream bus structures; thin form factors and tight bend radii for minimal physical interference with other subsystems; and ground testing is considerably less complicated as OHPs are relatively insensitive to gravity and can be verified without expensive, time-consuming spacecraft gimbling.

“ThermAvant’s next generation technology is a significant enabler for SWAP constrained missions, especially in VLEO. The comparative increased performance of OHPs to more traditional legacy TCS allows cutting edge missions like Albedo’s to break additional barriers and continue to increase the pace of innovation for our mission sets. We are excited to leverage this VLEO TCS on our Clarity constellation of ultra-high-resolution VLEO imaging satellites, allowing Albedo to collect more imagery for our customers due to the reduced maintenance, extended component lifespan, and overall enhanced system performance.”

– AyJay Lasater

Co-Founder/Chief Technology Officer of Albedo Space

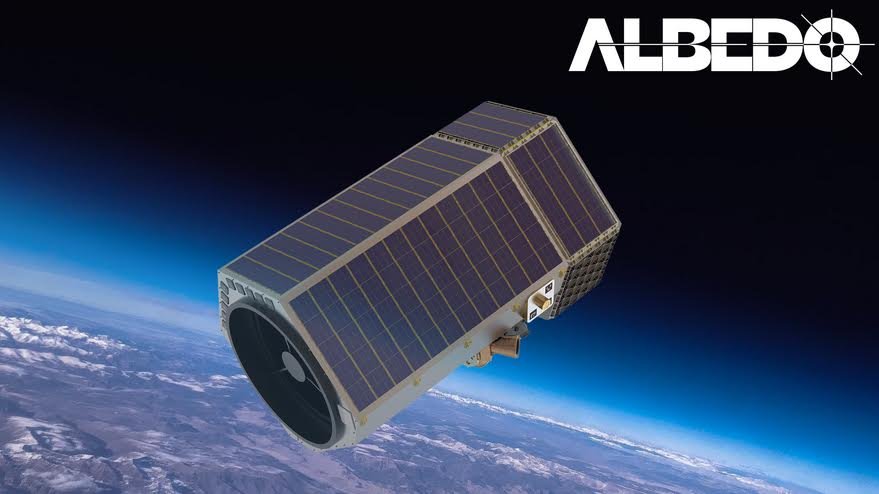

About Albedo

Albedo is building a constellation of VLEO satellites that will capture both visible and thermal imagery at the highest resolution commercially available (10 cm/pixel visible and 2 meter/pixel thermal infrared). With image quality levels equivalent to today's aerial imagery, Albedo's imagery is a key input for industries such as defense/intelligence, precision agriculture, HD mapping, property insurance, power line wildfire prevention, and numerous climate applications. For more information, visit albedo.com or contact media@albedo.com.

About ThermAvant Technologies

ThermAvant Tech. is the world’s leading oscillating heat pipe (OHP) developer and manufacturer. We embed OHPs into materials to maximize thermal-mechanical performance and minimize Size, Weight, Power plus Cost. Aerospace firms and U.S. agencies use OHPs to deliver more power in smaller packages without temperature constraints imposed by status quo solutions. For more information, visit thermavant.com or contact sales@thermavant.com.